Non-ferrous metal raw materials

Production of non-ferrous metal raw materialsBrass rod smelting: round rod, mesh rod, straight rod, square rod, hollow tube

Aluminum rod smelting: various conductive aluminum rods, industrial aluminum profiles from smelting to extrusion and drawing

Hot forging, cold extrusion

Hot forging, cold extrusionUsing intermediate frequency heating, it can process various materials such as copper, aluminum, iron, stainless steel, etc. Using as few extrusion processes and intermediate annealing times as possible, with the lowest material consumption, the highest die life and production efficiency, cold extrusion conforms to the technology required extrusions.

Main equipment capacity

hydraulic press:(800T/1000T/1500T);

- 1500T:1set

- 1000T:1set

- 1 electric screw press Screw press:1set

- 800T:1sest

- 300T:1set

- 200T:1set

- 80T:1set

- 63T:2sets

- 25T:2sets

Workshop Overview - Hot Forging Workshop

Multi-position cold heading

Cold heading: According to the theory of metal plastic deformation, a certain pressure is applied to the metal blank at room temperature to cause plastic deformation in the mold cavity, and it is formed according to the specified shape and size. The pier is mainly used for mass production of fasteners such as nuts, bolts, etc. It has good surface quality, high dimensional accuracy, high efficiency and stable product quality.

For the upsetting of small precision parts, the mass production of non-standard screws for fasteners, etc., with high efficiency and obvious cost advantages

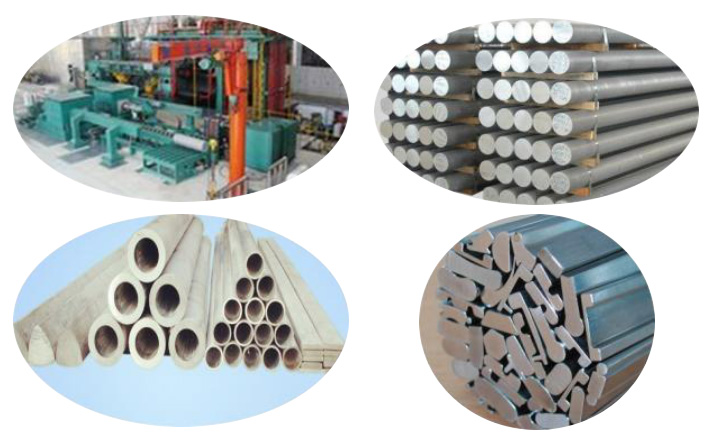

Stamping

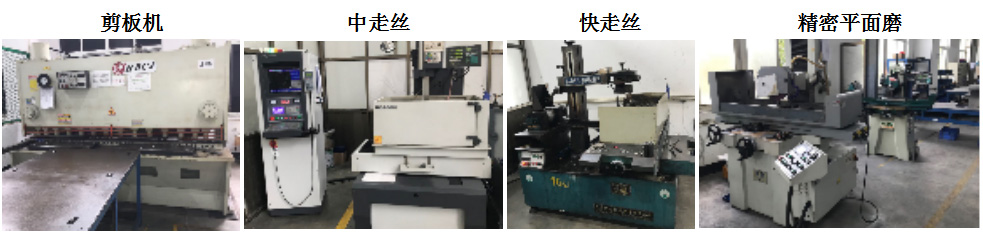

StampingPneumatic punch, shear plate, middle walk wire, fast walk wire, plane grinding, etc

Pneumatic punch

Precision Machining

Precision Machining

Through the machining center where the spindle axis of the advanced CNC machining center is perpendicular to the worktable (it can also be parallel by changing different tools),

It has various processing functions such as milling, boring, drilling (drilling, expanding, reaming), power thread, countersinking, etc. It is mainly suitable for processing various precision parts.

Widely used in electrical equipment, medical equipment, electronic equipment, optoelectronic communication equipment, automation equipment, auto parts, electronics, electrical appliances, home appliances and other fields.

The company's precision processing equipment includes: CNC lathes, multi-function vertical and horizontal machining centers, turning centers, vertical milling machines, precision surface grinders, lathes, computer core-moving machines, etc.

CNC lathe: 140 sets CNC lathe: 140 sets

Vertical Machining Center: 65 VMC: 65sets

Turning center: 8 sets TMC: 8 sets

Horizontal Machining Center: 8 HMC: 8sets

The equipment is imported from Japan and Taiwan, with high precision and high stability

The equipment has 4-axis machining capability. The maximum machining diameter is ∮ 20mm, and the maximum spindle stroke is 200 mm.

Welding, riveting

Welding, riveting

Welding ability

1 welding robot

Manual soldering station 5 groups

Various types of argon arc welding and carbon dioxide shielded welding can be carried out

Riveting capacity

Heat Treatment/Surface Treatment

Heat treatmentMain equipment capacity

Solid carburization

Liquid carburization

Gas carburizing

Deep carburizing

Nitrocementation

Nitrocarburizing

Anticorrosive nitriding

Aluminium alloy quenching

Adopt computer to control

Surface treatment:

· The whole cast· Sand blast

· Polishing

· Oil removing

· Rust protection

· Silver plating

· BOblack oxide

· Pickling passivation

· Manganese is high temperature phosphating

· Nobleness degree cleaning

Workshop Overview—Heat Treatment Workshop

Assembly - Final Assembly

Assembly - Final Assembly